Researchers at Polish Academy of Sciences develop polymeric, biodegradable and drug-coated stents

Scientists from the Polish Academy of Sciences in Zabrze are working on biodegradable polymers that can be used to obtain cardiovascular implants in the form of drug-coated stents.

The implants are being developed at the Centre for Polymer and Carbon Materials of the Polish Academy of Sciences in Zabrze (Silesia) - in the Laboratory of Polymer Biomedical Materials, headed by Professor Janusz Kasperczyk.

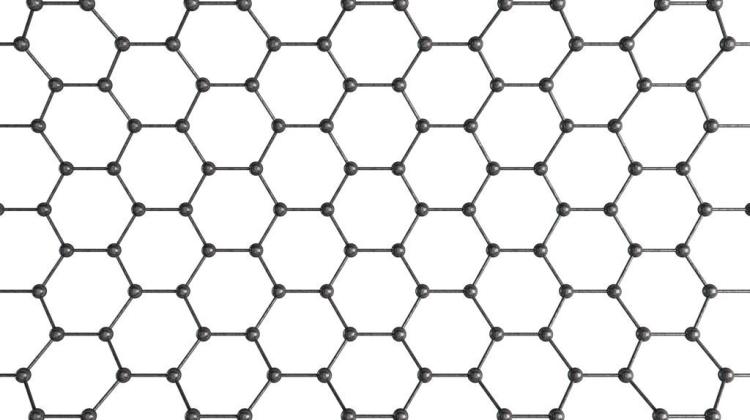

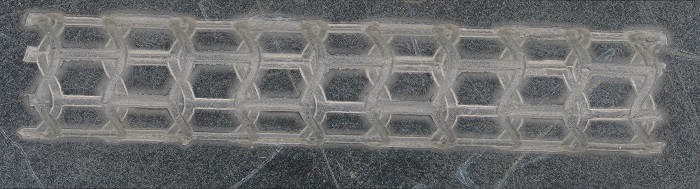

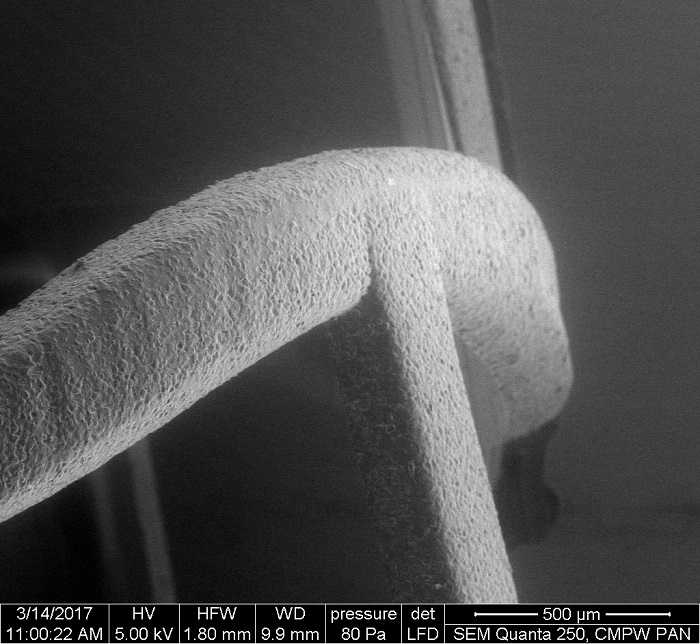

A stent is a medical implant used to maintain the proper shape of arteries affected by atherosclerosis, and to prevent their re-narrowing. It looks like a cylinder with a diameter of approximately 3-8 mm and a thin mesh structure, 150-200 microns thick.

Dr. Mateusz Stojko from the Centre for Polymer and Carbon Materials says that stenting is now one of the most common and best methods of treating coronary heart disease, one of the most common causes of death in developed countries.

Jakub Włodarczyk from the Centre for Polymer and Carbon Materials adds that currently stents are made of various materials, most often metal.

'The main problem with metal stents, however, is that the foreign body remains in the body forever, which is problematic, also due to the risk of thrombosis and the need to take medications permanently. Moreover, more and more young people suffer from coronary artery disease, which creates the likelihood of having to re-apply the stent in the same place, and in the case of metal stents, such surgical re-intervention is usually impossible,’ Włodarczyk says.

The team from Zabrze proposes polymer stents made of a biodegradable material - that is, a material that will be absorbed and excreted by the body after being introduced into a blood vessel and fulfilling its function of maintaining its shape.

According to the researchers, although stents themselves made of polymeric and biodegradable materials are not new (they were approved for clinical use a few years ago and then withdrawn due to the problem of incomplete and incorrect dissolution in the human body), the solution proposed by Professor Janusz Kasperczyk's team is innovative for several reasons.

The first is the type of material - terpolymer, i.e. a polymer consisting of three types of basic units called monomers. 'With their help, we can control the properties of the entire material so that it meets all the requirements of biomedical polymers: no toxicity, degradability in biological conditions, and sufficient mechanical strength. Additionally, our material is largely amorphous, like glass, which facilitates uniform degradation,’ Włodarczyk says.

The synthesis (combination) of three materials into one is also performed at the Centre for Polymer and Carbon Materials PAS in Zabrze, where scientists have been working on biomedical polymers for years.

The second innovation is the method of obtaining stents using microinjection technology.

'Currently, a commonly used method for producing polymer stents is extrusion and subsequent laser cutting. In turn, the micro-injection we use, although considered a very difficult technology to use, is much faster and one-stage (with each thermal treatment, the polymer loses its properties), and therefore less energy-intensive. The only remaining issue is material loss, because we have a large amount of waste during the printing itself. This waste is not suitable for reuse as a biomaterial, but it is suitable for other applications. We are still working on that,’ Włodarczyk says.

Another advantage is the speed of the process. The stent made with this method is currently manufactured in about 3 minutes. Then it must be covered with a coating that contains a drug against restenosis (re-narrowing of blood vessels after the procedure), tightened on the so-called balloon (an element that is inserted into blood vessels during surgery) and sterilised.

Covering the stent with a coating that contains a drug is another feature of the described implants. 'Although metal stents with the addition of drugs are already available, when the material of the implant and the coating with the drug is the same (i.e. a biodegradable polymer), there is no risk of delamination, which increases the treatment safety and effectiveness. It is worth emphasising that the drug administered in this way acts on this specific place, limiting the undesirable effects on the rest of the body, and we can also control the speed of its release,’ says Dr. Mateusz Stojko.

In the researchers' opinion, their proposed method of producing stents fits into the trend of developing personalised medicine.

'"Medicine is largely moving towards personalisation, and our stents allow to adjust some parameters to the patient's needs, for example when it comes to differences in the drug release rate due to differences in the metabolism of younger and older people,’ Stojko continues.

The research on the stents is aimed at acquiring new knowledge. However, scientists hope to establish cooperation with an interested entity in order to conduct preclinical research. 'We already have the technology for obtaining biodegradable polymer stents, the scientists say.

PAP - Science in Poland, Agnieszka Kliks-Pudlik

akp/ bar/ kap/

tr. RL

Przed dodaniem komentarza prosimy o zapoznanie z Regulaminem forum serwisu Nauka w Polsce.