Scientists from Warsaw University of Technology involved in work on new European battery

Source: www.pw.edu.pl

Source: www.pw.edu.pl

Batteries consist of three basic components: two electrodes (cathode and anode) and the electrolyte connecting them. To improve the properties of the entire battery, scientists from around the world, including experts from the Warsaw University of Technology, are working on modifying the materials used to make these components.

As part of the European project ASTRABAT, experts from the Warsaw University of Technology are exploring the possibilities of developing batteries with solid electrolyte, made of such raw materials and in such a way that their mass production can take place in Europe. Why do we need this? As they explain, it is primarily about strategic security and safety of use of batteries.

A Warsaw University of Technology press release says that a battery with a solid electrolyte is safer because it does not contain liquid or flammable or leakable components. Thanks to this, it can be widely used in the automotive industry (in electric vehicles), electronics and for renewable energy. Additionally, if such an electrolyte could be produced in Europe, from raw materials readily available in Poland, it would make the Polish market independent of the supply chain and manufacturing process, which is influenced by political and economic factors, among other things.

As part of the ASTRABAT project, a concept of a completely new battery with greater thermal stability and a higher safety level was created. Instead of a liquid electrolyte, it uses state-of-the-art polymer electrolytes and a durable ceramic filler.

The new battery is also more environmentally friendly because of the recycled materials. During the work, great emphasis was placed on research into less polluting components, greener production processes and lower consumption of elements such as cobalt. The scalability of materials synthesis processes was also a priority.

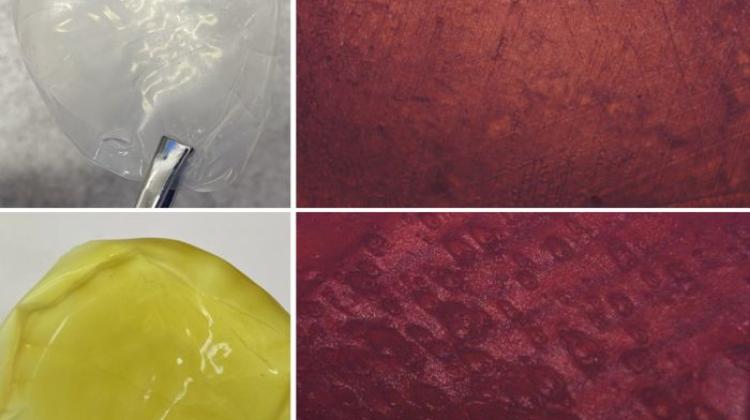

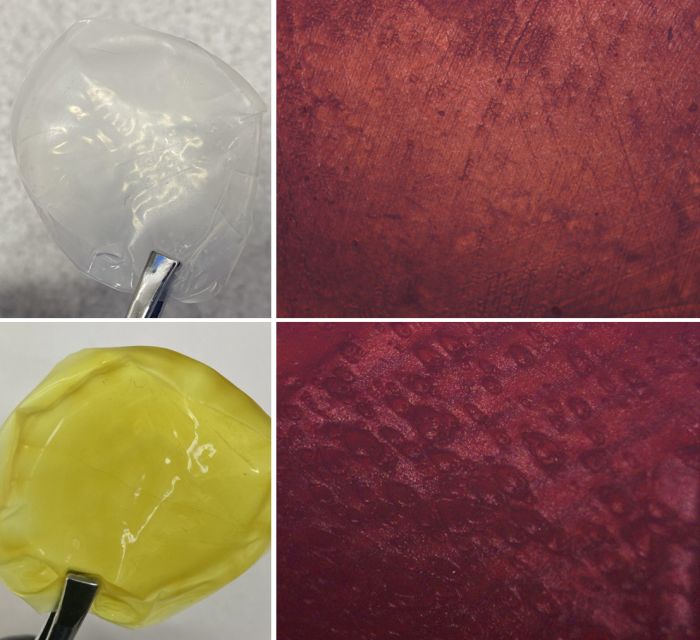

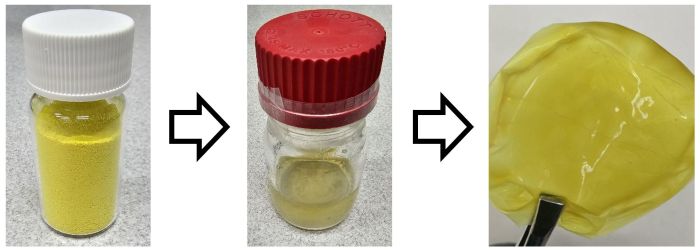

The task of scientists from the Warsaw University of Technology was to design and synthesize a lithium salt and a plasticiser from an ionic liquid, and then increase the scale of their production. They also tested a key ingredient, the solid electrolyte, which distinguishes the new battery from existing solutions. The Warsaw team also tested the anolyte and catholyte components that occur only in cells with solid electrolyte and contain an anode and a cathode, respectively.

'Salts and plasticisers for electrolytes are unique solutions originally developed and patented at the Warsaw University of Technology. The fluorine-free salts developed as part of the project are the first in the world to meet the requirements of the battery industry,’ says the head of the research team, Dr. Leszek Niedzicki.

The Warsaw scientists say that although the first prototype was developed in 2022, the device still requires improvements: problems with the interface and mechanical stability remain to be resolved. Overcoming them is a necessary condition before introducing the product into mass production. Therefore, in their opinion, the realistic date for implementing the technology on a larger scale is 2030.

The most important studies and solutions developed as part of the ASTRABAT project are included in the technical manual, which is available on the website.

Fourteen partners from eight European countries participated in the project. The consortium consisted of leading research centres and universities, as well as automotive, battery and energy companies. The Warsaw University of Technology was the only organisation to represent Central and Eastern Europe. (PAP)

Katarzyna Czechowicz

kap/ bar/ kap/

tr. RL

Przed dodaniem komentarza prosimy o zapoznanie z Regulaminem forum serwisu Nauka w Polsce.