Polish researcher uses spent coffee grounds to create ceramic thermal insulation materials

Spent coffee grounds have a very high calorific value and contain a large amount of water, which is why they are great as additives to clay in the production process of porous ceramic materials with thermal insulation properties. Dr. Ewelina Kłosek-Wawrzyn from AGH UST is working on the optimisation of production of such materials. The first test results are very promising, the university reports.

According to the university representatives, the idea of using ground coffee waste as a clay additive in the production of porous ceramic materials is not new. It has already been discussed in the literature. The challenge for engineers is to design this process to obtain a material with desired thermal parameters, while simultaneously meeting the mechanical resistance standards. The materials used in construction must remain rigid under various stresses and adding too many easily burning materials to clay reduces its resistance.

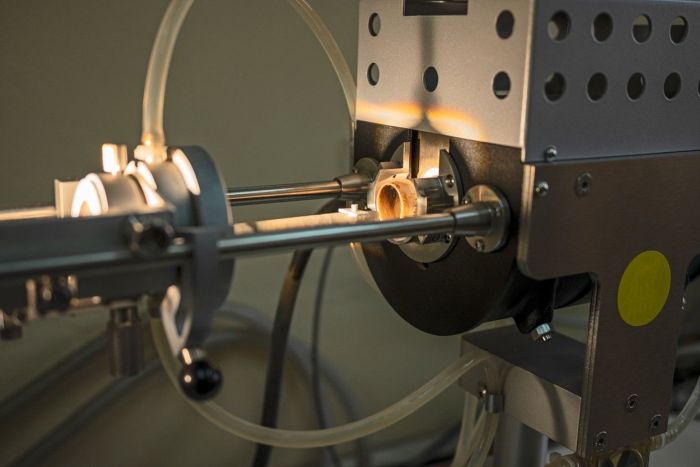

Dr. Kłosek-Wawrzyn conducts her research together with colleagues from the Department of Building Materials Technology at AGH UST. Under laboratory conditions, she prepares ceramic material samples, choosing various proportions of the porousator (spent coffee grounds) to achieve the desired porosity. Subsequently, the prepared samples are meticulously analysed.

'Above all, we study the efficiency of the heat transfer coefficient using a stationary heat flow meter', says Dr. Kłosek-Wawrzyn explains. 'We test its compressive strength because building materials are exposed to various mechanical forces. We analyse its density and porosity, but we also apply other techniques, including scanning electron microscopy, to find out how the material under investigation looks like in microstructure, that is, what its distribution of pores is and whether there are cracks. As a result, we can regulate the production process and shape the direction of future research projects'.

The researcher explains that pores in construction materials strongly affect their thermal insulation properties: 'Transfer of heat can occur by means of conduction, convection, and radiation', she says. 'In building materials, heat transfer occurs mostly by means of conduction. The heat moves from a higher-temperature zone to a lower-temperature zone. If the material is porous, the heat encounters obstacles on its way, which hinder conduction. To act efficiently, pores must be less than 0.5 mm in diameter to eliminate convection as an additional mechanism of heat transfer. Generally, closed pores are the best for this, but this doesn’t have to be a rule. Everything depends on their diameter and direction'.

And how are these pores in ceramic materials obtained? Dr. Kłosek-Wawrzyn explains that in ceramic materials, they form as a result of burning clay mixed with additives. These additives burn out during the production process, leaving micro-spaces filled with gas that has a much lower heat transfer coefficient than a solid material.

In traditional construction ceramics, the additive used to obtain the porous structure is usually cellulose pulp or sawdust. Replacing them with spent coffee grounds, in addition to secondary waste management, allows to save considerable amounts of energy and water used in the production process.

'Traditional construction ceramics uses additives that burn out during the production process', says the author of the project. 'In addition to porosity, by burning, they add extra heat, which reduces the use of gas in the production process. The used coffee grounds show a much higher calorific value than sawdust and other commonly applied additives used in construction ceramics, allowing us to minimise the amount of heat used in the production process'.

'Furthermore, used coffee grounds collected from coffee shops, for example, are wet and contain from 55 to 60 percent of water. Usually, when building materials are made with the use of clay, we have to add water to make it plastic. Here, however, if we can organise the entire production process appropriately, adding water won’t be necessary at all', she adds.

The spent coffee grounds used in the AGH UST project come from two coffee shop chains and are mixed together during the production process. 'Although they come from different sources, the only difference between them is the content of water; whereas they are identical in terms of granularity and very similar in terms of calorific value', says Dr. Kłosek-Wawrzyn.

According to the International Coffee Organization, each year the world produces about 10 million tons of whole bean coffee. The AGH UST representatives add that if we had ground the entire year’s harvest and made coffee from it, we would have been left with an equal mass of coffee grounds, amplified by the volume of unfiltered water. This waste is not environmentally neutral because when it is deposited in landfills, it emits methane, a gas that contributes to global warming.

Therefore, projects are being carried out around the world to develop ways of secondary management of coffee waste. After proper preparation, it can be used as a fertiliser, biodegradable material for industrial production, or as a biofuel. The AGH UST researcher's idea to use of them as an ecological raw material for the production of porous ceramic materials is responds to this need.

Dr. Kłosek-Wawrzyn believes that her solution has not only an ecological, but also a practical value. 'The building materials currently manufactured show, in my opinion, too high strength parameters, which translates to higher thermal conductivity', the researcher explains. 'In my material, I want to find a balance between thermal conductivity and strength. However, I am not aiming for high constructions; one- or two-storey is enough, where the material strength doesn’t have to be that high, which makes it possible to increase porosity and, consequently, lower thermal conductivity'.

The first research results are very promising. 'Due to the fact that I have completely modified the production process, I can put much more used coffee grounds into the material than has been described in the literature to date and obtain significantly better thermal parameters of about 0.15–0.25 watts per meter-Kelvin', concludes Dr. Kłosek-Wawrzyn.

PAP - Science in Poland

kap/ zan/ kap/

tr. RL

Przed dodaniem komentarza prosimy o zapoznanie z Regulaminem forum serwisu Nauka w Polsce.