Invention from Warsaw University of Technology will help rebuild bones

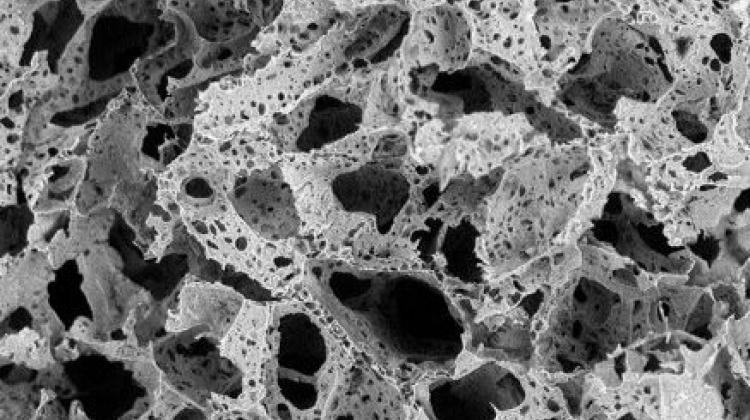

Sample image of the internal morphology of the implant made with SEM microscope. Fig. Monika Budnicka

Sample image of the internal morphology of the implant made with SEM microscope. Fig. Monika Budnicka

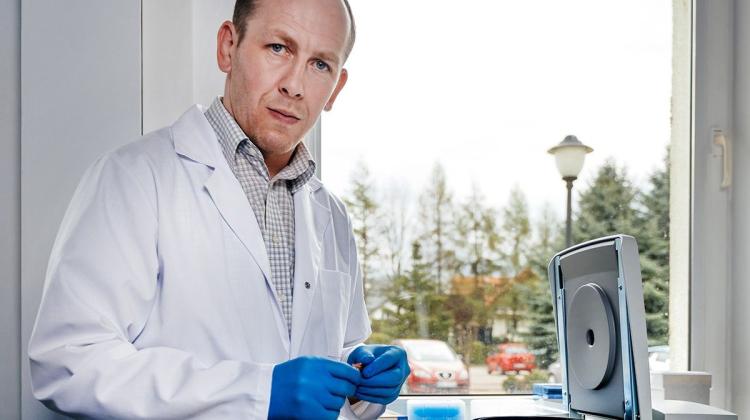

A small, light foam created at the Warsaw University of Technology looks inconspicuous, but has an important role: it is a "scaffolding" that helps in bone reconstruction. It will also be easier to use it in the operating theatre than other bone substitutes, say its creators, scientists from the Warsaw University of Technology.

So-called bone substitutes are common in today`s medicine. These are implants that help people who are missing some bone tissue for some reason to return to full fitness. They are used in cases of damage that will not repair themselves. Doctors must induce the body to rebuild bone by placing a special implant in the tissue.

Most scientific papers concern 3D printed implants. Their advantage is the possibility of obtaining any shape tailored to a specific defect visible in the X-ray image. However, 3D printing takes several hours, so it is not possible to adjust the size of the implant in the operating room conditions. Such an implant must be prepared before the surgery starts. Ideally, the implant should be possible to adjust to the shape of the defect during the procedure. Scientists from the Faculty of Chemistry, Warsaw University of Technology propose a solution to these problems.

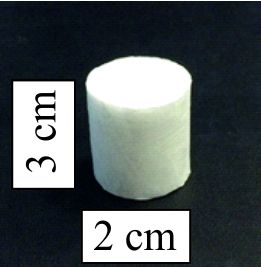

The result of their work looks quite inconspicuous - it is a small oval foam with a volume of about 10 cubic centimetres, weighing less than one gram. "The lightness of this material is determined by its porosity - in the material there are many empty, interconnected channels" - explains Monika Budnicka, PhD student at the Warsaw University of Technology and the main creator of the implant. "These channels are very important because our material is designed to serve as +scaffolding+ for bone-rebuilding cells, so firstly, they have to fit in it, and secondly - we need to include an outlet for cell metabolism products" - she says.

Unlike rigid 3D printed implants, the material developed at the Warsaw University of Technology is flexible. It can be soaked with water - and therefore also with various biological ingredients. The developed implant is made of the same material that is used for 3D printing, but due to the used manufacturing method, it has completely different characteristics. "The material is made of a lactic acid-based polymer that is naturally present in our body. After some time, the implant should break down in the body" - explains Dr. Agnieszka Gadomska-Gajadhur from the Faculty of Chemistry, Warsaw University of Technology.

Picture of the entire implant. Fig. Monika Budnicka

The implant should also be much easier to use in the operating room. "The implant is relatively flexible, so it can be cut during surgery - that is not possible with 3D implants" - notes Monika Budnicka.

"The orthopaedist opens a sterile implant and begins to operate. If the defect is larger, he puts a larger part in. If its is smaller, he cuts it to shape, decides on the size of the implant during the procedure" - describes Dr. Gadomska-Gajadhur. She adds that the implant can also be introduced with an endoscopic method, through small incisions.

The idea for a new material came from the reconstruction procedure of the anterior cruciate ligament in the knee. Chemists from the Warsaw University of Technology got the idea from orthopaedist Prof. Krzysztof Ficek. "During the reconstruction of the cruciate ligament, bone channels are drilled - that is, the bone is damaged - in order to attach a new ligament. These bone channels are usually filled with +tissue mosaic+, an amalgam of tissues most often taken from a few deceased people" - explains Dr. Gadomska-Gajadhur.

Collecting material from other people causes problems. This material is not always of the best quality: the donors can include, for example, an older person whose bones are no longer in good condition. The bone substitute created by Warsaw chemists does not have this drawback. On the contrary - it can be personalized.

"This means that we can take cells from the patient we want to implant, extract stem cells, for example from its fat cells, apply them to this implant and transplant into bone channels - so that bone is rebuilt more quickly, the tissue is better anchored and the patient recovers faster" - says Dr. Gadomska-Gajadhur.

The invention has been successfully tested in the laboratory. But before it can be marketed, it has to be researched further and more funds are needed for that. "Foreign companies are interested in the idea, but of course we would like to find a Polish investor, because it is a Polish invention" - the researchers add.

PAP - Science in Poland, Katarzyna Florencka

kflo/ agt/ kap/

tr. RL

Przed dodaniem komentarza prosimy o zapoznanie z Regulaminem forum serwisu Nauka w Polsce.