Scientists from Lodz University of Technology have created a unique technology for modifying bone implants

Photo: Fotolia

Photo: Fotolia

Scientists from Lodz University of Technology in cooperation with Medgal of Białystok have developed the technology for coating bone implants with carbon-silicon coating on the industrial scale. Such coatings improve the biocompatibility of implants that are anti-allergic and additionally stimulate bones to coalesce faster.

Scientists from Lodz University of Technology in cooperation with Medgal of Białystok have developed the technology for coating bone implants with carbon-silicon coating on the industrial scale. Such coatings improve the biocompatibility of implants that are anti-allergic and additionally stimulate bones to coalesce faster.

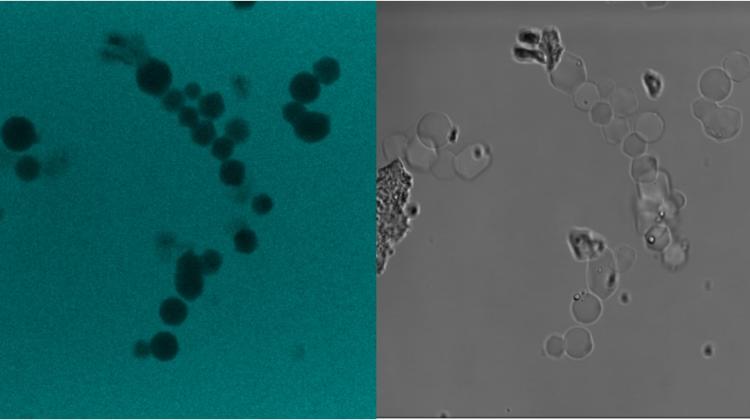

Institute of Materials Engineering at Lodz University of Technology is one of the most famous Polish centres engaged in the production of carbon coatings using technologies such as radio frequency plasma. In collaboration with industry partner - the leading medical implant manufacturer, Medgal of Białystok - scientists have developed and patented the technology of producing biocompatible silicon containing diamondlike carbon coatings (Si-DLC).

"Our technology has enabled us to achieve homogeneous, well-adhering coatings for the surfaces of medical implants" - explained Dr. Damian Batory from the Institute of Materials Engineering of Lodz University of Technology.

He emphasized that steel and titanium alloys are used to produce medical implants. "They contain all kinds of elements, additives that not necessarily healthy for our body. The use of a sealed carbon coating protects the body against the migration of sensitising metals" - he noted.

In addition, it positively affects the functions of the body, in the case of bone implants it stimulates the bone to coalesce faster. In turn, introducing silicon into the structure of carbide coatings allows to improve their properties by increasing bacteriostaticity and improving haemocompatibility.

Lodz researchers and their industrial partner were the first to implement this technology in industrial production. "Our technology for producing coatings based on carbon and silicon is innovative on a global scale" - said Dr. Witold Kaczorowski from the Institute of Materials Engineering, Lodz University of Technology.

The products thus produced were subjected to a full cycle of tests provided for in the Law on Medical Devices, i.e. mechanical, physicochemical, pre-clinical and clinical studies. As a result, Medgal has received the CE certification for a wide range of medical implants with carbon-silicon layers.

Currently, such modified bone implants for the treatment of bone fractures and injuries, are in the company\'s offer. Medgal sells its products to dozens of countries. (PAP)

szu/ ksk/ kap/

tr. RL

Przed dodaniem komentarza prosimy o zapoznanie z Regulaminem forum serwisu Nauka w Polsce.