The Polish-French electrochemical capacitor combines high energy and power

A modern and safe lithium-ion capacitor has been developed by scientists from Poland and France. The device combines the advantages of typical batteries (stores a lot of energy) and an electrochemical capacitor (provides high power).

The project participants were scientists from Poznań University of Technology - Prof. François Béguin and Dr. Paweł Jeżowski (Power Sources Group) and scientists from the University of Nantes (France).

Electrochemical capacitors, like batteries, are used to store energy. If you compare energy storage systems to runners, batteries are like marathon runners and capacitors are like sprinters. Batteries accumulate a lot of energy and release it slowly. In turn, the task of capacitors is to provide a large amount of energy in a very short time (about one second).

In an electric car, capacitors allow to start the vehicle and start driving or recover energy during braking (so-called regenerative braking), while the battery allows the vehicle to drive hundreds of kilometres. The disadvantage of capacitors is that they are not capable of storing as much energy as batteries (in the same mass or volume unit); batteries, in turn, have a long charging time (energy accumulation).

THE LONELINESS OF THE LONG DISTANCE SPRINTER

Currently, cars need both batteries and capacitors. In the future, they may be replaced by a single device.

Back to sports comparisons - this capacitor is something like a perfectly organized runner who does a great job on both short and long distances. "We have designed a universal system that fills the +technological gap+ between batteries and electrochemical capacitors" - declared Dr. Paweł Jeżowski in an interview with PAP.

Professor Béguin explained: "The most noticeable use of lithium-ion capacitors in public life will be buses and trams powered by such devices. This will allow to reduce the number of traction lines and increase the number of low-emission vehicles".

The new capacitors could also replace the current solutions used in electric tools such as drills, saws and screwdrivers. And who knows, they might also be useful in mobile devices, such as laptops.

The results of the study have been published in the prestigious scientific journal "Nature Materials" http://nature.com/articles/doi:10.1038/nmat5029.

UTI-LIT-ARY SYSTEM

"The first buses equipped with ULTIMO lithium-ion capacitors from JSR Micro are already being tested in Belgium" - said Dr. Jeżowski. Those devices, however, are built completely differently than the lithium-ion capacitors developed by the Polish-French team.

Currently available solutions use lithium in its pure form (lithium is the lightest metal). And lithium in this form is not the most suitable material to be used on a large scale. Its presence in a device can lead to the system overheating (in case of overcharging or excessive discharge) and as a consequence ignite the electrolyte, and in combination with water and air - it can cause an explosion.

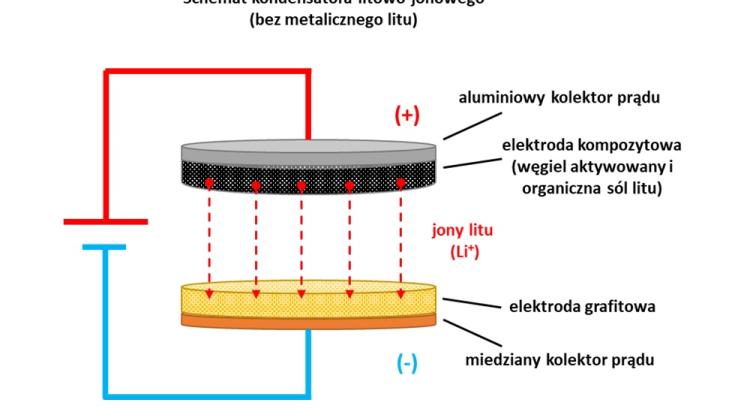

In the publication, researchers proposed how to construct a lithium-ion capacitor using organic lithium salts instead of its pure metallic form. Lithium salt is a material that does not pose a threat to the user. An additional advantage of this solution is that it is easy to recover lithium salt from the capacitor. Its residue dissolves in the electrolyte. In the recycling process, it is enough to recover the electrolyte from used equipment. Thanks to this, the substance will not go into the environment and it can be processed.

CHARGED WITH POSITIVE ENERGY

A capacitor based on this idea has excellent properties when it comes to charging and discharging. "We have demonstrated that we can carry out 20,000 charging and discharging cycles" - says Dr. Jeżowski. He noted that lithium-ion batteries have a lifetime of about 1,000 such cycles. "That is why mobile phone or laptop battery life decreases with use. The electrochemical reactions that occur in the battery are not fully reversible, there are always small losses" - the researcher added. In this respect, the new lithium-ion capacitor is expected to be much better. Charging it takes only 5 minutes.

The lithium-ion capacitor developed by the Polish-French team reaches the energy of 40-60 Wh/kg (for comparison, a lithium-ion battery stores 250 Wh/kg, and an electrochemical capacitor - 10 Wh/kg). The delivered power of the new device is 2-5 kW/kg (to compare, batteries 0.5-1 kW/kg, and electrochemical capacitors 10 kW/kg).

The construction of such a capacitor can be presented as follows: the positive electrode is made of a mixture of activated carbon (responsible for the storage of energy in a double electrical layer) and organic lithium salt. The anode (negative electrode) consists of graphite made of several graphene layers. During the first charging cycle, lithium ions derived from the organic lithium salt are intercalated (introduced) between the graphene layers. They allow to obtain a sufficiently low potential of this electrode, and in conjunction with a high potential of the positive electrode - to accumulate a large amount of energy.

PAP - Science in Poland, Ludwika Tomala

lt/ agt/ kap/

tr. RL

Przed dodaniem komentarza prosimy o zapoznanie z Regulaminem forum serwisu Nauka w Polsce.